Wood Product Manufacturing Major

Become part of a premier wood processing program in the US. Whether you're drawn to design, management, or fabrication, this 4-year program is guaranteed to equip you for success in the workforce.A top wood processing program in the US

Whether your interest is design, management, or fabrication PSU's Wood Product Manufacturing program will prepare you for the workforce.

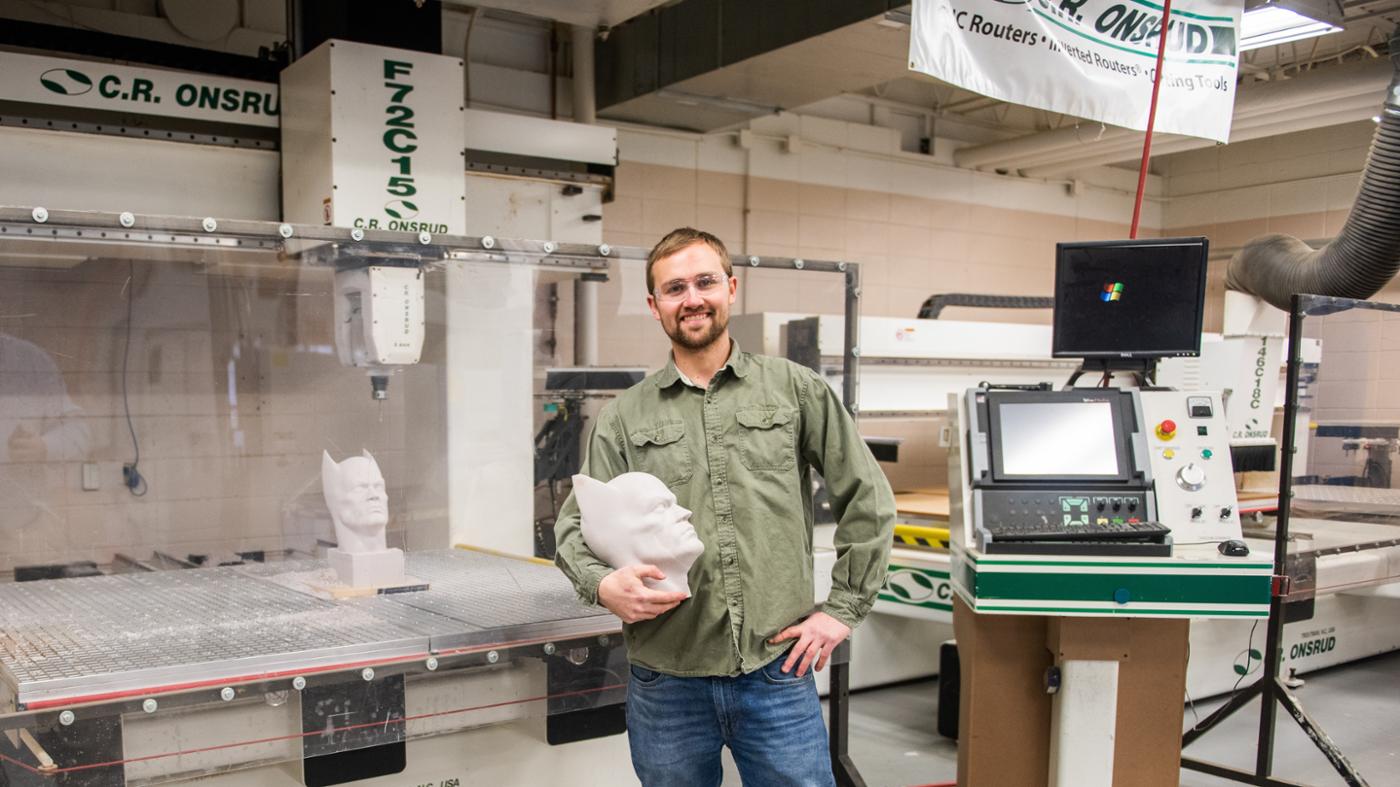

Our curriculum is hands-on, leveraging state-of-the-art equipment. Coursework is production-based. It blends classroom theory with real-world products and processes.

Download the Wood Product Manufacturing Viewbook.

Strong network in industry leaders

Benefit from PSU's robust network of industry leaders in Wood Product Manufacturing, eager to recruit talent like you. Many students secure paid summer internships through our connections. Expand your network at trade shows, conventions, facility tours, and conferences.

Curriculum Outcomes

- Analyze characteristics and cell structure of wood samples to determine identification and properties

- Demonstrate comprehensive knowledge of safety and laboratory practices associated with all equipment in the AMMT laboratories.

- Recognize and fabricate joinery and assembly practices associated with architectural woodworking projects

- Develop 2D architectural submittal drawings using AutoCAD software

- Produce, evaluate and interpret G-code for CNC machinery

- Apply specialized technical knowledge to troubleshoot and provide routine maintenance to standard woodworking machinery

- Display comprehensive knowledge of theory, setup and execution of CNC and moulder operation

- Evaluate veneer panel species and matches

- Explore innovation to mass produce one product more efficiently

- Fabricate cabinetry types to given specification and applications

- Use computer software to design and manufacture more efficient and accurate

- Read and interpret architectural blueprints, developing a scope of interest

- Demonstrate understanding of the entire woodworking manufacturing process

Wood Product Manufacturing Careers

- Area Supervision

- Assembly

- CNC Operation

- CNC Programming

- Design

- Drafting

- Engineering

- Estimating

- Finishing

- GM/Ownership

- Installation

- Machine Operation

- Plant Management

- Project Management

- Production Management

- Sales

Our program has a nearly 100% graduate placement rate.

Key Corporate Supporters and Recruiters: 1220 (TN), Adams Group (FL), 3M Abrasive & Adhesives, Advanced Fixtures Incorporated (AFI), Advantage Architectural Woodworking (KS), AWI Heart of America, Bearwood Concepts (OK), Blake Clotia (KS), BLUM, Cabinet Vision, Castle, Cohen Architectural Woodwork (MO), CR Onsrud (NC), Custom Wood Products (KS), Dimensional Innovations (KS), Denray, Dekker, Dodds, EGR (OK), Franklin Adhesives, Festool, Gator Millworks (LA), Gemini, Genesis Hospitality Corp (CO), Glenn Reider (WI), Goebel Fixture (MN), Grandview / Woodmont Cabinetry (TX), Great Lakes Tooling, HAFELE, High Country (CO), Hollywood Woodwork (FL), High Country (CO), Hoffman, Hollywood Woodwork (FL), idX (International), Independent Stave Company (MO), Indiana Architectural Plywood Inc. (IN), JLT Clamps, Katalyst Group Inc. (KS), Kerfkore, Kremlin, Leitz, LMT Onsrud, Laminate Works (KS), M. Bohlke, MARTIN, MasterCAM, Master Wood Craft Cabinetry (TX), Mikron, Mortensen Woodwork Inc. (GA), MSW Inc. (MO), Mikron, Parenti & Raffaelli (IL), R.D. Henry & Company (KS), RCS Millwork (TX), Republic Elite (TX), RSA Solutions, RT Machinery, Rulon International (FL), SCM Group (GA), Schmalz, Stiles, TigerStop, Timesavers, Twin Oaks Custom Cabinets (MO), Veneer Services, Vortex Tooling, Weinig-Holzher, Wood Systems (OK), WMIA.

Additional information

Wood Product Manufacturing Degree Map download

Catalog – see catalog for the School of Technology and Workforce Learning